Are you having trouble bonding certain types of plastics?

Despite what many may think, not all plastics are the same, or even similar. When it comes to adhesive bonding, some plastics are much more challenging to work with than others. Before selecting an adhesive for your plastic, you need to take into account the nature of the plastic first. This is because some very commonly used plastics, such as polyethylene (PE) and polypropylene (PP) are hydrophobic.

“A plastic that’s scared of water?!” we hear you say. Not quite. If a plastic is hydrophobic, it means that it has a low surface energy, and therefore poor wettability – instead of a liquid spreading out smoothly and evenly over the surface, it will clump together and resist spreading. Think of a freshly waxed car bonnet that gets rained on, and you’ll know exactly what we mean by a hydrophobic surface! This is a problem for adhesives, since they are liquid and need good surface wettability to properly ‘soak’ into a substrate and form an effective bond.

Which kinds of plastic are harder to bond?

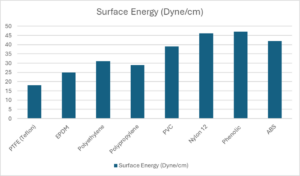

Plastics known as polyolefins are the likely culprits you’ll come across as being challenging to bond well. These include the aforementioned PE and PP, as well as LDPE (Low Density Polyethylene) and EPDM (Ethylene Propylene Diene Monomer rubber.) These plastics have an enormous variety of uses and are found everywhere, from plastic bags and bottles, pipes and containers, all the way to more hidden uses in carpets, roofing and decking. Nylon (also known as polyamide) is another type of plastic which is harder to bond. While not a polyolefin, nylon exhibits the same poor surface wettability as polyolefins, as well as absorbing the moisture from the air around it, which makes adhesion especially difficult.

The table below shows the surface energies of a variety of common plastics. The energy of a surface is measured in dynes/cm. The lower the surface energy, the harder it is for an adhesive to ‘wet’ a substrate. Normally, an adhesive needs to have a lower surface energy than the substrate to form an effective bond.

Traditionally, low surface energy plastics require quite intensive (and often expensive and/or dangerous) processes to pre-treat the surface before an adhesive can be used. These vary from plasma or corona treatment, to chemical etching and flame treating the surface of the plastic. With Permabond, thankfully there’s no need to continue with these costly, complex and sometimes dangerous surface pre-treatments.

How Permabond can help you overcome these challenges

We offer a variety of options for easily bonding polyolefins. Let’s start with our TA46XX range of structural acrylic adhesives. These bond exceptionally well to polyolefins such as PP and PE, as well as to other types of plastic, metals and many other materials. The way that TA46XX works to bond polyolefins is rather unique – through a reaction with oxygen, these adhesives chemically ‘attack’ the surface of the polyolefin to form an incredibly strong bond. This process therefore completely negates the need for costly surface pre-treatment before bonding.

TA46XX Range Features & Benefits:

- Bonds low surface energy plastics

- No need to flame, corona or plasma treat surfaces before bonding = cost & process saving

- No primer required

- Ideal for bonding a wide range of surfaces

- Some strength on PTFE (Teflon)

- Easy 1:1 mix ratio – apply manually or use with automatic dispensing equipment

- Non-hazardous for transport = easier shipping & storage

- Full cure at room temperature

- Good impact strength

- Good chemical resistance

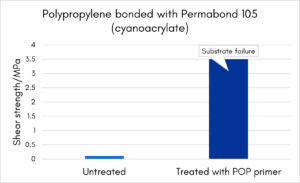

Another option for challenging plastics would be to use a cyanoacrylate (also known as ‘superglue’) with Permabond POP Primer. POP works by heating up the cyanoacrylate so that it can better bond to polyolefins. In the graph below, you can see the difference in shear strength on PP when bonded with Permabond 105 both with and without POP primer. Without POP, the bond is very weak and would break easily. With POP, you get substrate failure, meaning that during strength testing, the polyolefin fails before the bond does.

For nylon bonding, you can use Permabond TA4550, a brand new adhesive that offers outstanding bonds on the three main types of nylon – 6, 6.6 and 12. Similarly to the TA46XX range, using TA4550 means no need for primers or surface treatment beforehand, saving both time and money. It has a high viscosity and as such works very well in vertical applications, as it won’t slump or sag once applied. It bonds nylon to itself, nylon to other substrates such as metals and plastics, as well as non-nylon bonding – its shear strength on steel is outstanding.

To find out more about Permabond’s adhesives for bonding challenging plastics, or to discuss your application, please don’t hesitate to get in touch with us!

Categories

Let’s Discuss Your Project.

"*" indicates required fields

Products

Technical Support

Permabond will help you select the right adhesive for your application.