Permabond is a global company and you will see both British and American spellings of words throughout this site. For the most part, my colleagues in the UK are very accepting of American spellings – until it comes to the word aluminum! In the interest of global peace I’ll use both spellings. Whether you call it aluminum adhesive or aluminium glue, Permabond has an adhesive bonding solution!

Aluminum Glue

Permabond manufactures several types of aluminum adhesives with various cure mechanisms to suit individual aluminum bonding needs.

Anaerobic Cure Mechanism

Anaerobic Adhesives cure in the presence of metal and absence of oxygen. These aluminum adhesives are ideal as sealants, retainers, and FIP gaskets. Because active metal is needed and aluminum can be passive, consider using an activator to accelerate cure. Low viscosity anaerobic sealants seal between aluminium tubes and end plates on heat exchangers, also, they are ideal for sealing aluminium tubing joints in refrigeration units – they have good resistance to refrigerant gas.

Moisture Cure Mechanism

Permabond manufacture two types of moisture cure aluminum glues.

- Cyanoacrylates are excellent aluminum glues, especially when a fast set time is desired. Cyanoacrylates or instant adhesives cure when the moisture on the surface activates the adhesive when it is pressed into a thin film.

- MS Polymers also cure with moisture. MS Polymers form weather resistant bonds to aluminum and have very low shrinkage rates. They are good for bonding large areas, providing a moisture seal and can even be painted over. They are popular in the construction industry.

Heat Cure Mechanism

Single component epoxy aluminum adhesives cure with heat to form high strength structural bonds. Permabond has aluminum color matched grades. They appear like welding or brazing.

Two Component Mix Cure Mechanism

Two component epoxy adhesives cure upon mixing. Specialty modified epoxy aluminium glues have low shrink rates to minimize read through in thin aluminium panel bonds. Toughened epoxy adhesives are suitable for bonding aluminium to other metals or substrates where there could be differential expansion and contraction.

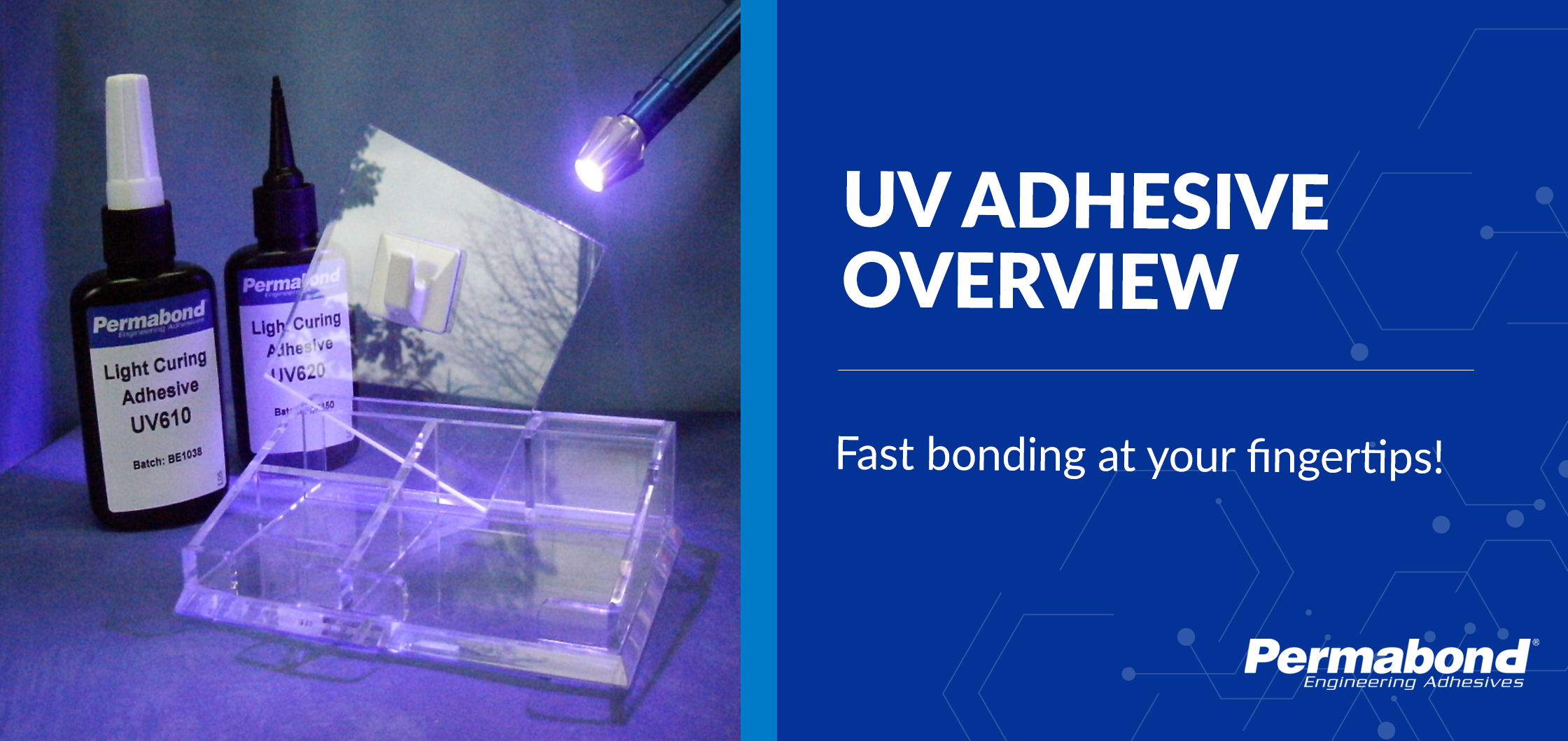

UV Cure Mechanism

Providing light can reach the bond area through the other substrate (like clear plastic or glass), many UV curables are excellent aluminum adhesives. If light can’t reach the entire bond because the adhesive is between two pieces of metal, consider a UV and Anaerobic cure adhesive such as Permabond UV7141.

So which Aluminum Adhesive is best for my application?

For more specific aluminum adhesive information click here. For individualized product recommendations, contact our technical team.

But wait – don’t go yet – one more tip to be sure the aluminum glue you choose works perfectly.

Either see below or watch the aluminum surface preparation video here.

Surface preparation can be important as aluminum surfaces often have an invisible oxide layer. Just wiping with a solvent cleaner is not usually sufficient if a high bond strength is sought. Many adhesives bond well to the oxide layer – however – removing the oxide layer can increase bond strength by 1000 psi or more.

Although solvent wiping in itself isn’t adequate, it is important to solvent wipe before abrading or grit blasting the surface to avoid pushing the oils or impurities into the fresh aluminum. After treatment – wipe surface again, to remove any debris.

There are a variety of solvents available to consider. Acetone, isopropanol, Permabond Cleaner A are all suitable. Avoid white spirit or meths as they can leave a residue.

For further help and advice, please contact Permabond.

Categories

Let’s Discuss Your Project.

"*" indicates required fields

Products

Technical Support

Permabond will help you select the right adhesive for your application.