Adhesive sustainability is something that design engineers and manufacturers are starting to pay greater attention to. As a rule, most adhesives are not environmentally friendly, being either petrochemically derived and/or solvent-based. The adhesives industry as a whole has been slow to adapt to changing customer demand for ‘greener’ products, partly hindered by the inherent nature of adhesives themselves. For Permabond, an adhesives manufacturer with a keen eye on the future, this is an area that we are actively looking to develop new solutions in.

CNSL – A breakthrough in adhesive sustainability

A fascinating development in the world of adhesive sustainability is the use of cashew nut shells as a completely natural, renewable resin product. More specifically, these shells produce a resin called cashew nut shell liquid (CNSL), a reddish-brown viscous liquid extracted from the honeycomb structure inside the shells. CNSL contains compounds such as anacardic acid and cardanol, which are then modified slightly to produce raw materials suitable for use in epoxy resin systems as the curing agents. The cured system behaves as users would expect from an epoxy resin system and will bond a wide variety of substrates including metals, woods and some plastics.

Permabond has developed a two-part epoxy, Permabond ET5393, which contains CNSL as its resin component. This adhesive bonds well to a wide variety of substrates and is particularly effective on stainless steel. Not only this, Permabond ET5164, our recently launched EU & FDA food-grade epoxy, also contains CNSL, and we are actively looking to include it in other new formulations.

Reducing waste and CO2 emissions with Medmix MIXPAC™ cartridges

Another exciting development is our upcoming switch to Medmix’s MIXPAC™ greenLine™ cartridge range for all two-part epoxies made at our Winnall production facility in the UK. These are made from up to 100% post-consumer recycled (PCR) or post-industrial recycled (PIR) plastics. The recycling of these plastics enables them to get a second life in the form of cartridges for our adhesives, all without compromising on performance in any way. Their sage green colour serves as a useful indicator and reminder of their more environmentally friendly nature.

Key benefits of using these cartridges are a reduced environmental impact, less waste and a lower carbon footprint. Transitioning across to using MIXPAC™ greenLine™ cartridges is a key part of Permabond’s strategy to leverage greener technology in the production of its products. They will start gradually coming into production very soon, so keep your eyes peeled!

Key Features of MIXPAC™ greenLine™ cartridges include:

- Up to 73% reduction in CO2 emissions in production

- Made with up to 100% recycled plastics

- Easy to use and dispense; no process changes needed

- High leak proofness and long-term stability

- Safe, quick and easy use

- Increased process safety

Major reduction in CO2 emissions from our Italian factory

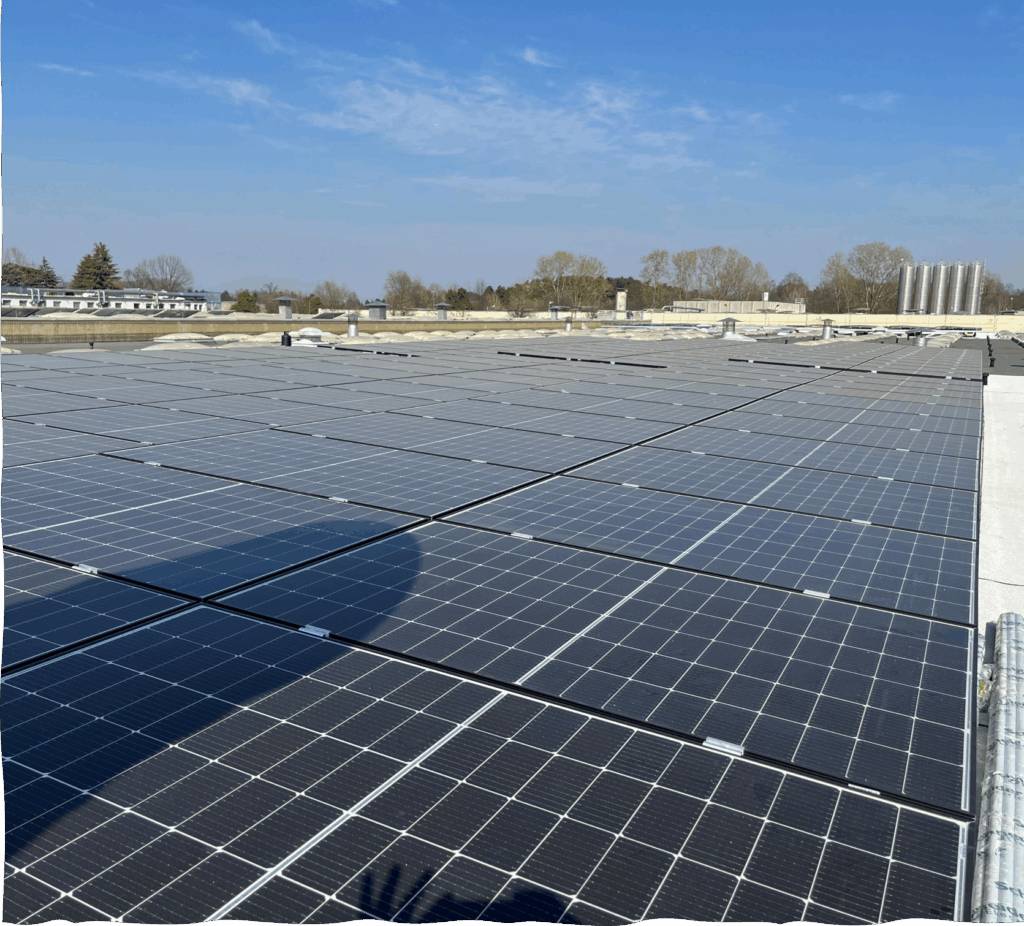

This isn’t an adhesive or cartridge change, but is worth noting nonetheless. Permabond’s factory in Italy recently installed solar panels across its roof, which has led to significant reductions in CO2 emissions – a whopping 94% decrease! In fact, the panels produce so much energy that we’re able to sell some back to the Italian grid! In real terms, before these panels were installed, producing a 50g bottle of anaerobic adhesive would have generated roughly 33 grams of CO2. Now, however, the same bottle generates just 1.8 grams of CO2. This is fighting climate change in action!

To conclude, it’s safe to say that making adhesive production greener and more environmentally sustainable is no easy task. However, it is by no means impossible, and these changes are a positive step in that direction. As new and innovative developments in the world of sustainability come to the fore, Permabond will continue to adapt and grow alongside them.

If you’d like to find out more about anything mentioned in this article or to discuss your application, please contact us.

Contáctenos

Productos

Encontrar un distribuidor

Los productos Permabond se comercializan a través de distribuidores en todo el mundo.

Certificado ISO

Permabond es una compañía que cuenta con la certificación ISO QMS Certified.