Tips for Bonding Polycarbonate with Industrial Adhesives

How to Bond Polycarbonate Polycarbonate PC is a great substrate for bonding with industrial adhesives. Its surface is receptive to adhesive bonding, and bond strength normally exceeds the actual substrate strength (meaning that when you try to pull the joint apart, the substrate breaks before the adhesive joint). Cyanoacrylate adhesives are often chosen as […]

Ceramic Bonding Adhesives

Permabond offers several toughened grades of ceramic bonding adhesives. Ceramic materials are inorganic compounds that are typically rigid and very brittle. They are generally electrically non-conductive and have good heat resistance and resistance to harsh chemicals. The brittleness of ceramics often calls for toughened grades of adhesive which can resist the different thermal expansion rates […]

How to Bond Brass

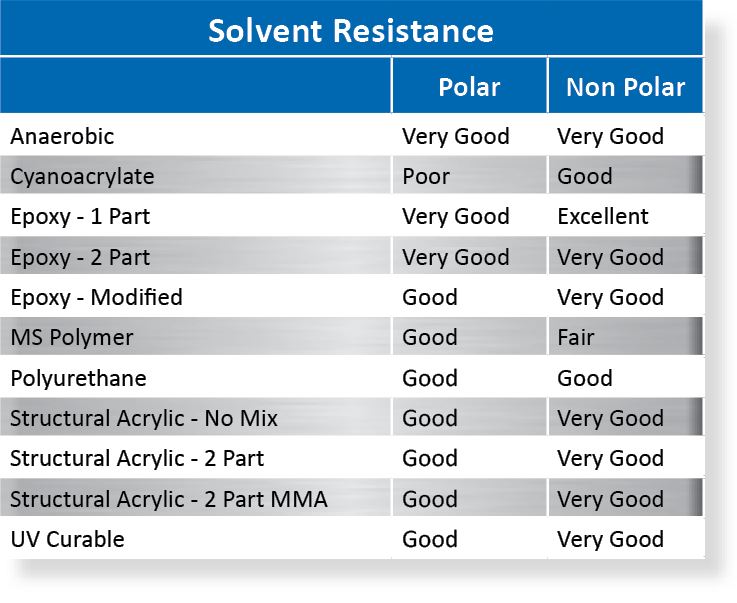

Bonding Brass Brass is an alloy comprising zinc and copper. It is non-magnetic, resists corrosion, and is malleable. Various industries have brass bonding needs. Applications include pipe joints, hydraulic fittings, heat exchangers, door locks and knobs, munitions, and musical instruments. A variety of different types of adhesives readily bond brass. Having so many options can […]

How to bond aluminum

When looking to bond aluminum, it is important to keep in mind that aluminum surfaces often have a weak, invisible oxide layer. Just wiping with a solvent cleaner is not usually sufficient if a high bond strength is sought. Adhesives bond well to the oxide layer – however – the oxide layer isn’t bonded well […]

How to Bond Stainless Steel

Stainless steel, or “inox steel” is a steel alloy containing chromium. It does not corrode, rust, or stain like normal steel. It normally is quite easy to bond and does not require much in the way of surface preparation; however, mirror-finish stainless steel can have very low surface energy and prove difficult to bond. Providing […]

How to bond polystyrene?

Many types of adhesives bond polystyrene. However, it can be vulnerable to stress cracking, so take care in the adhesive selection, joint design, and adhesive cure process. Polystyrene Properties: Surface energy: 41mJ/m² Maximum service temperature: 65°C Softening temperature: 107°C How to bond polystyrene? Polystyrene can generally be bonded as received without cleaning. If cleaning is […]

How to bond silicone with Permabond cyanoacrylates.

What is silicone? Silicone is a rubber-like elastomer with high-temperature resistance. It is difficult to bond, and the only adhesives which adhere well are silicone based adhesives and cyanoacrylate adhesive after the silicone has been primed with Permabond POP. How to bond silicone? First, wipe with isopropanol to remove any release agents. Then apply POP […]

How to bond PVC with industrial adhesives

How to bond PVC – To understand how to bond PVC we first need to understand what variety of PVC is at play. PVC or polyvinyl chloride is available in many forms. For adhesion purposes, we will loosely categorize PVC as: Plasticized PVC = PVC Rigid PVC = RPVC or uPVC (unplasticized PVC) “Green” PVC […]

How to bond polyurethane

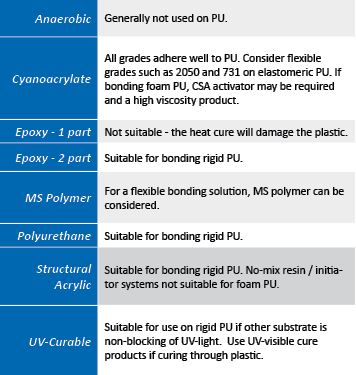

How to bond polyurethane? Polyurethane (PU) is available in various guises – thermoform or thermoset and comes as a rigid solid, foam, or a soft elastomer. It is an easy-to-bond material provided you select the adhesive to suit the type of PU you are bonding. All grades of Permabond Cyanoacrylates adhere well to PU. Consider […]

Adhesives for PTFE

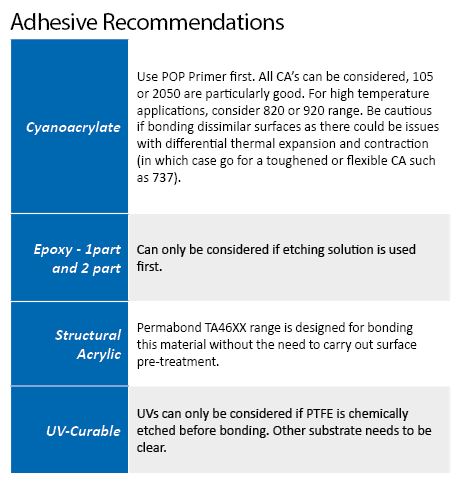

How to bond PTFE? Permabond has adhesives for PTFE. PTFE (Teflon® or the proper name “Polytetrafluoroethylene”) is a notoriously difficult material to bond as it is non-stick by nature. It is common in applications where high temperature and/or exposure to harsh chemicals will be an issue. Adhesives for PTFE: Structural Acrylics – Permabond structural acrylics […]

How to bond polypropylene

How to bond polypropylene Polypropylene can be difficult to bond with standard adhesives. Permabond developed the Permabond TA46XX range to bond low surface energy plastics. Permabond TA4605, TA4610, TA4611, and TA4631 all bond untreated polyolefin surfaces. These adhesives are ideal for bonding polypropylene and polyethylene – without the need to carry out costly surface pre-treatment […]

How to bond phenolic – Successful phenolic bonding

How to bond phenolic? Phenolic is fairly easy to bond therefore there are many adhesive types are available (and listed below). When it comes to PCBs there are several points to consider in addition to adhesion. Most importantly: Electrical Properties Thermal Conductivity Heat Resistance Non-corrosive Nature Flame Resistance Etc… Review these points with an […]