Application Tips

Permabond has over 50 years of adhesives experience. We’ve amassed a list of application tips for handling and storage of adhesives, suitable substrates, temperature effects, surface preparation, and adhesive removal during this time.

With this knowledge, Permabond has become a uniquely capable resource for communicating the positive effects Permabond products have in many areas around the globe. Recognizing the significance of this responsibility, we have produced this section to serve as an introduction to the most common considerations regarding the proper utilization of our products which include:

Within each technology section, there are various products to suit individual application requirements. Our chemists are available to assist in selecting the best product for your application or providing more application tips. Please get in touch with us with any questions.

Adhesive Storage and Shelf Life Conditions

Proper Adhesive Storage Means Greater Profits

Review these recommendations prior to selecting an adhesive for your application, and follow them whenever possible. The shelf life of each Permabond adhesive is based on our experience with that product under controlled conditions.

Therefore, we are certain that these adhesives, when stored per our guidelines, will maintain their performance over the course of the shelf life given. Unfortunately, if you have not stored the adhesive according to these recommendations, we often cannot give reliable information about its performance.

Adhesive Shelf Life

Permabond advises storing each adhesive type within the temperatures indicated below. However, please note that the shelf life and storage temperature may vary based on the package size. Therefore, use the following information as a guide only and contact Permabond’s technical team for any specific product information you require.

Permabond Anaerobics

Permabond Cyanoacrylates

Permabond ET Two-Part Epoxy

Permabond ES One Part Epoxy

Permabond MS MS Polymers

Permabond PT Two Part Polyurethane

Permabond Structural Acrylics

Permabond UV Curable Adhesives

Suitable Substrate Surfaces

Common Substrate Surfaces and the Suitability for Adhesive Bonding

Aluminium and its Alloys

Conventional Steel Alloys

Zinc-plated Steel

Treated Zinc-plated Steel

PVC-coated Steel

Stainless Steel Alloys

Painted Steel Panels

Thermoset GRPs

Acrylic-faced Thermoset GRPs

Wood-faced Thermoset GRPs

CRFPs

ABS

Nylon

Polyolefin

Permabond TA4605, TA4610, TA4611, and TA4631 bond polyolefin substrates with no surface treatment! These products create bonds strong enough to have the plastic stretch and fail before the bond. See the image here.

Polyurethane

PVCs

Temperature Effects on Adhesives

Temperature Effects on Adhesives During Storage, Application, Curing, and Use.

Controlling Cure Rates and Production Speed Effect of Environmental Temperature

Cyanoacrylates cure using surface moisture and are less affected by temperature. However, the humidity and substrate can affect the cure rate of cyanoacrylates.

Heat cure schedules for single-component epoxies can be found on the technical data sheets.

You can accelerate the cure rate of a 2-part epoxy with heat.

For effects on other adhesive technologies, such as structural acrylics, MS Polymers, and polyurethanes, please contact us.

Service Temperatures

For more information on how temperature may affect your application, please contact our technical team.

Surface Preparation

Common Guidelines to Prepare Surfaces for Bonding with Permabond Adhesive

Surface Preparation – Solvents

Surface Preparation – Mechanical

Surface Preparation – Abrasion

Surface Preparation – Dry Blasting

Surface Preparation – Wet Blasting

Surface Preparation: Non-mechanical

Surface Preparation – Plasma Discharge

Surface Preparation – Plasma Chamber

Surface Preparation – Laser

How to Remove Permabond Adhesive

The three primary means to remove cured adhesive are:

- Chemical

- Temperature

- Stress

Depending on the type of adhesive and the substrates or assembly in question, choose the easiest way to remove cured adhesive from the methods below. For example, if trying to degrade a cyanoacrylate bond, keep in mind that they are brittle and often don’t have much peel strength. Also, they have poor resistance to polar solvents such as water. Warm soapy water works faster!

If you want to get an epoxy bond to fail, water isn’t going to help much. High temperature may be a better option. Many two component epoxies will fail at or below 200°F. If using heat to destroy a single component epoxy bond – raise that to 400°F.

Adhesive Removal by Adhesive Type

Anaerobic Threadlockers:

Anaerobic Gasketmakers:

Anaerobic Thread Sealants aka Pipe Sealants:

Anaerobic Retaining Compounds:

Removing a stubborn Anaerobic Adhesive:

NOTE be certain that no solvent residue is present on the parts, and remove the solvent container from the work area prior to using the blow torch. Always store the solvent in tins with the lid on in a flame-proof cabinet.

These recommendations assume all component parts are metal.

Cyanoacrylate Instant Adhesives:

Soak skin bonded with cyanoacrylate in hot soapy water. For stuck fingers, roll a pencil gently between the fingers – do not peel. We don’t recommend using solvent on hands as it will de-fat the skin. Soapy water is not only good for removing adhesive from skin; if your components can take a nice long bath, they will de-bond over time. To shorten the time, use hot water.

Please contact Permabond for information on how to remove the toughest bonds.

Contactez-nous

Produits

Assistance technique

Permabond vous aidera à sélectionner la colle qui convient à votre application.

Pour trouver un distributeur

s produits Permabond sont vendus par l'intermédiaire de distributeurs dans le monde entier.

Permabond est certifié ISO QMS compagnie.

Vous pouvez obtenir une copie de notre certificat ISO

Latest Posts

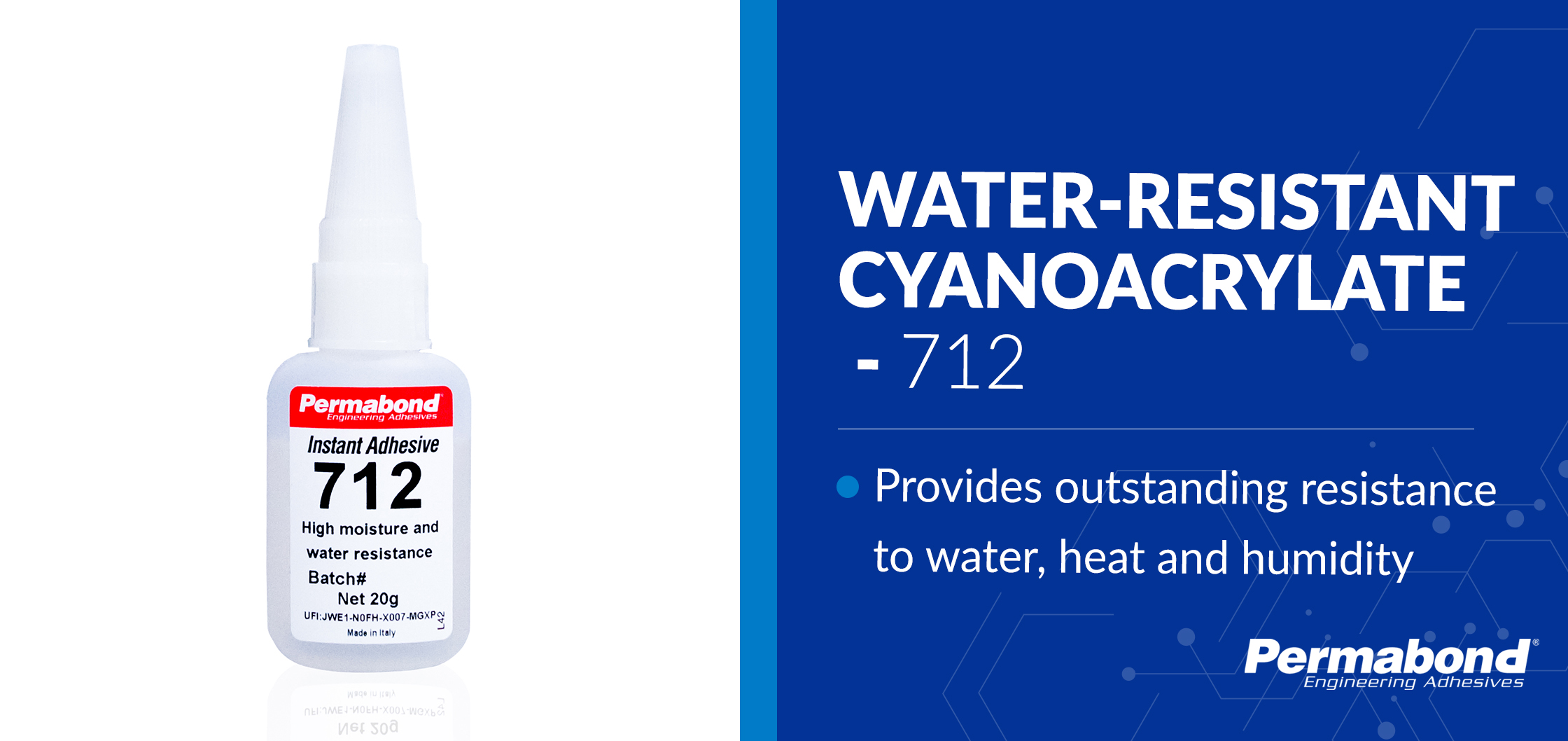

Permabond 712 – A Powerful Water-Resistant Cyanoacrylate

Permabond 712 is a water-resistant cyanoacrylate that has been a highly popular product since it was first launched last year,

Methylene Chloride: Its Dangers and What to Use Instead

Methylene Chloride (also known as Dichloromethane) has long been used in the manufacture of adhesives. Its main purpose is that

Introducing FDA & EU food safe adhesive, Permabond ET5164

Permabond Europe is pleased to announce the official launch of Permabond ET5164, a 1:1, two-part FDA & EU food safe