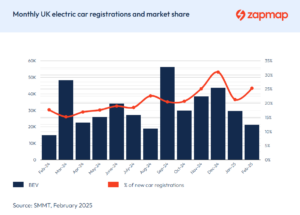

A hot market

We live in a world where technology is advancing at a rapid pace. One area where this advancement is most apparent in everyday life is in cars. We’ve gone from a world where petrol and diesel-powered cars were the norm, to over 20% of new UK car sales being either fully electric or hybrid on average, according to ZapMap.

Electric vehicles (EVs) make extensive use of electric motors, with a constant push from this market for smaller, more lightweight and efficient motors. Smaller, lighter motors tend to get a lot hotter than their larger counterparts, as they have far less ability to dissipate the very high heat produced by these vehicles. Motor manufacturers are therefore facing ever-increasing demand for higher and higher temperature resistance, and motors with Class H insulation are in particular highly sought after by EV manufacturers – these can withstand temperatures up to 180°C and are ideally suited for use in these vehicles.

Our Solution – High Temperature Magnet Adhesive, Permabond ES5516

To meet this industry demand, Permabond has developed a new high temperature magnet adhesive – Permabond ES5516. This heat-curing single-part epoxy adhesive offers outstanding hot strength performance, maintaining high-strength structural bonds at 180°C. This makes it ideally suited to the bonding of class H electric motor magnets, including those in permanent magnet synchronous motors. Other uses include fixing any small close-fitting parts where there is no ability to mechanically clamp.

A highly unique feature of this adhesive is its dual activation. Once the adhesive has been applied, the bond can first be sealed or ‘tacked’ with UV light, before being subsequently heat cured. This ‘tack strength’ helps to prevent adhesive outflows from bonded joints before curing. It’s also of great help in applications where accurate alignment of parts is required, as parts can be tacked in place before entering the heat-curing process.

Key Features of ES5516:

- Excellent hot structural strength performance at 180°C – ideally suited to electric motor magnet bonding, as well as other high heat applications

- UV activation as well as heat cure – reduces adhesive outflows and allows for optimum alignment of parts before bonding

- Toughened; high strength on metals and composites

- Lightly thixotropic for accurate alignment of parts

- Excellent vibration resistance

- High shear strength

- Good resistance to chemicals

Target Applications:

- Electric motor magnet bonding, e.g. for EVs

- Sensors

- Boilers

- Heat Pumps

- Weaving and tooling machinery

- High temperature conveyors and pipelines

If you’d like to find out more about this product or to discuss your application, please get in touch with us.

Kontaktieren Sie uns

Produkte

Technischer Beratungsdienst

Permabond hilft Ihnen, den richtigen Klebstoff für Ihre Anwendung auszuwählen.

Regionale Vertriebshändler

Produkte von Permabond sind über Vertriebshändler in allen Teilen der Welt zu beziehen. Hier können Sie unsere Vertriebshändler finden.