Epoxies, Cyanoacrylates, and several other technologies provide excellent adhesion to metals. But, acrylic metal bonding adhesives are often a good choice not only for the strong bonds to metals but also for the variety of curing options available, which can optimize production processes.

Many acrylic adhesives form strong bonds to a variety of metals – often – choosing the best metal bonding acrylic adhesive, is based on the best way to apply and cure the adhesive.

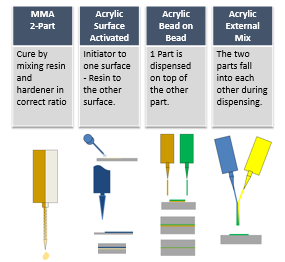

Many 2 part acrylic adhesives have a short pot life, said differently they begin to cure very quickly. In this case, it is best to dispense these adhesives via static mix nozzles onto one component then assemble the components quickly. This is ideal for many high speed processes.

Some 2 part acrylic adhesives are MMA based. Although this type can provide high bond strength to plastics, they are flammable and have a distinctive strong odor.

Permabond TA452 is a non-flammable low odor adhesive which provides up to 3,500 psi (24 N/mm2) shear strength on steel. It has a nozzle life of 2-3 minutes and develops strength very rapidly, achieving 80% of full bond strength in 75 minutes.

Permabond TA4246 is a No-Mix adhesive which is used in conjunction with Initiator 46 to form strong bonds to metal, glass, magnets, and composites. With no gap, TA4246 develops 80% of its strength in an hour. Full strength on steel is over 5000 psi (35 N/mm2) TA4246 is an MMA based adhesive, so there is a distinctive odor.

If you aren’t bonding plastic, consider non-flammable TA4590 along with Initiator 44. Full strength on steel is 3600 psi (25 N/mm2). Achieve 80% of the strength in under an hour and handling time (0.3 N/mm2) in under a minute.

The ability to remove parts from fixtures/jigs in under a minute can greatly improve production efficiency.

Never mix the initiator with the adhesive.

If the above instructions aren’t clear, see the curing instruction video.

With a controlled process that provides adequate mixing of the adhesive, shear strength values on steel of 3600 psi (25 N/mm2) can be achieved. With no gap, handling time of 90 seconds or less is possible.

Permabond TA437 can be used without initiator when bonding metals. It is a single component structural acrylic adhesive, primarily for bonding metals, ferrites, and ceramics. When the use of the activator is not desirable, the material will cure anaerobically in a close-fitting joint /in the presence of metal; the fixture time will be 5-10 minutes.

The typical fixture time of TA437 when used with Initiator 41 is 20-30 seconds. The fast fixture time of TA437 makes it an ideal adhesive for high-speed production lines. This product provides high strength, tough, durable bonds with good impact resistance.

Shear strength on steel – 3000 psi (20 N/mm2)

For assistance in choosing the best metal bonding adhesive for your application, contact Permabonds technical team.