Anaerobic adhesive resistance to environmental factors is generally very good. In selecting the right adhesive for each application, we are often challenged in finding an adhesive or sealant that can withstand the demanding environmental conditions of the application. However, when the right adhesive for the application is an anaerobic adhesive – we can generally say – BRING IT ON!

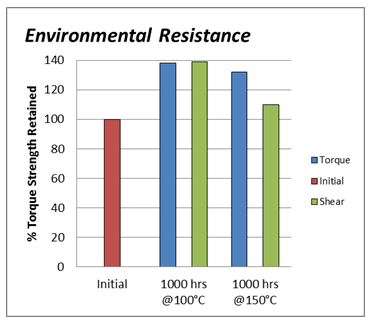

Anaerobic adhesives are single component liquid or semi-liquid adhesive that cure to a solid plastic when confined between two metal surfaces. The cured adhesive bonds and seals the metal components by filling all of the air space in the joint. Once fully cured many environmental conditions that would destroy other adhesives actually make the anaerobic adhesive stronger.

Anaerobic adhesives and sealants vary in strength, colour, viscosity, gap fill, set speed, and temperature resistance to suit industrial adhesive and sealant application needs.

Anaerobic Adhesives and Sealants are used as threadlockers, thread sealants, form in place gaskets, and retaining compounds. Industrial applications for each of these expose the adhesive to various chemicals.

As you can see below, anaerobic adhesives perform quite well after exposure to many common chemicals.

For further help and advice, please contact Permabond.